Tagore Road, Rajkot, Gujarat

-

GST No. 24AABFT1169N1ZZ

| Business Type | Manufacturer, Exporter, Supplier |

| Warranty | 1 Year |

| Capacity | 3 Ton/Day |

| Voltage | 415V |

| Click to view more | |

Product Details

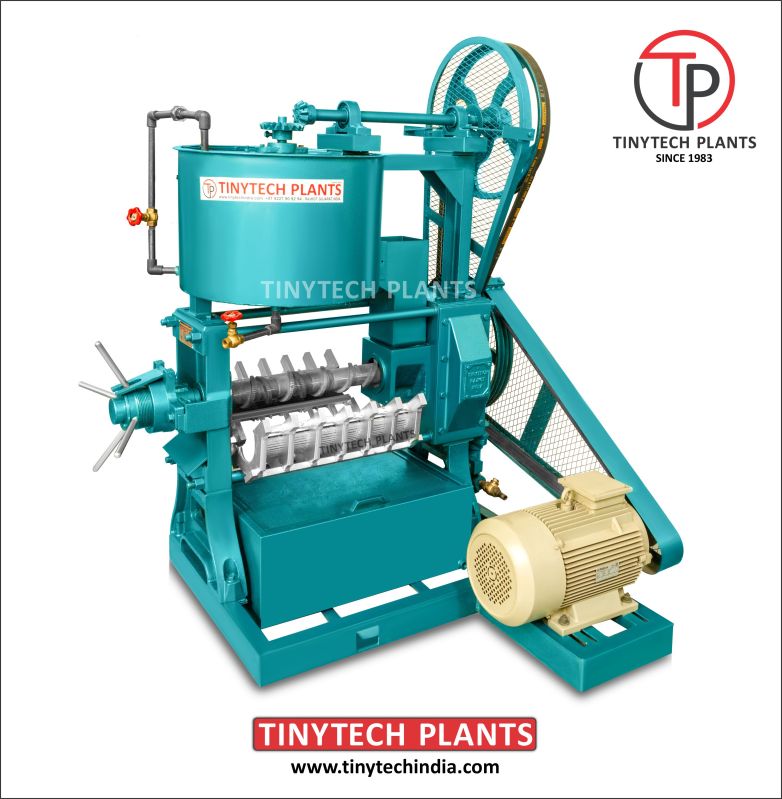

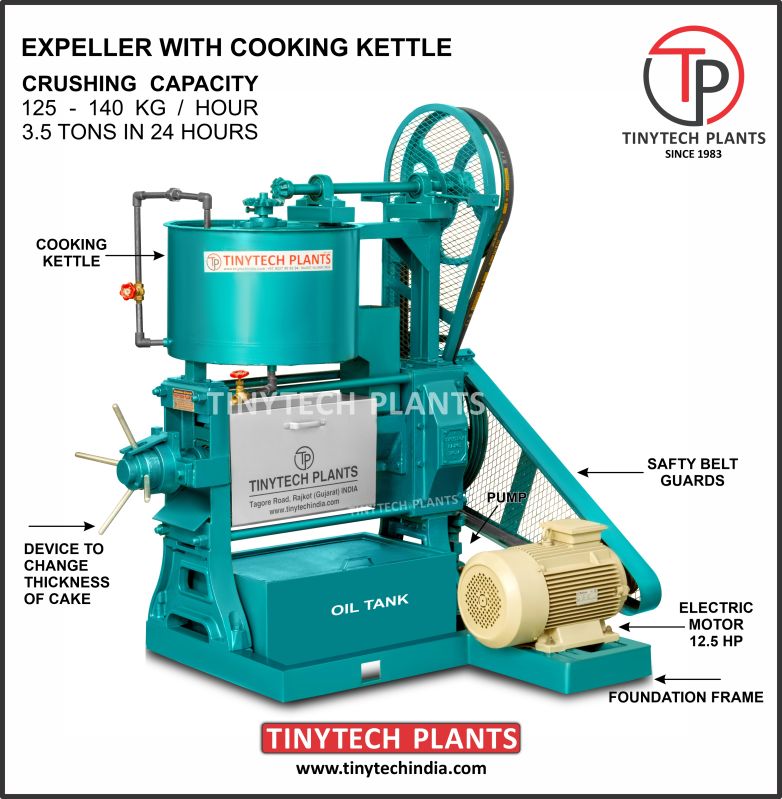

Expeller

It crushes oil seeds and produces best quality cooking oil and cake. It is the central part of the whole extraction plant.

Oil Expeller chamber size 22 x 4 crushes about 150 kg oilseeds producing oil and oil cake. Oil falls down in the small rectangular tank which is kept below the expeller and oil cake comes out from another side. Generally, for oil seeds having oil content more than 25% are crushed twice in the expeller for maximum recovery. During the first crushing thickness of cake is kept about 8~10 mm. And during the second crushing thickness of cake is kept about 3~4 mm.

Cooking Kettle

Cooking kettle is mounted on the expeller and its driven by expeller. It heats and cooks the oil seeds by outer steam from the boiler or by electricity. A little steam / water is also added to the oil seeds to increase moisture content to optimum level. which makes the crushing process easy and smooth

Cooking kettle has 3 functions,

1. It can hold 40 kg seeds and heated up by steam so that seeds get moisturized till the center of the seed due to steam pressure which is responsible for optimum oil extraction from the seeds.

2. You can increase or reduce flow of seeds going to the expeller so feeding control.

3. Seeds will fall on the magnet before entering the expeller which will save expeller from any iron parts to get damaged as iron part will stick to the magnet. This is an excellent facility with cooking kettle.

Special Facilities / Features In Tinytech Expeller

- Chamber cage opens on hinges simply by tilting of chamber halves. Drudgery of lifting of heavy weights of clamping bars and chamber halves are totally eliminated.

- Thickness of oil cake can be changed while running of expeller. This is unique facility. It enables to change thickness of cake while running of expeller. This is unique facility of Tinytech expeller.

- Oil pump is now integral part of oil expeller and hence no separate pump required.

- Due to ready foundation frame, No foundation of any machine required in the ground. So Installation becomes easy & plant can be started within 24 hours. Also you can shift machine easily from one place to another as and when required.

- 6 taper roller bearings make expeller very sturdy and durable. No ball bearings fitted anywhere.

- As expeller is very compact, it is economical to import by air freight for land locked countries.

- Feedbox mouth has been made bigger so that expeller can crush cotton seeds effectively.

- Main pulley Shaft diameter is 62 mm which is highest in the industry.

Looking for "OIL EXPELLER WITH COOKING KETTLE" ?

Explore More Products